The South Rail Systems Alliance (SRSA) Bristol division has completed a two-week project at Stoke Gifford, successfully implementing a pioneering approach to sustainable rail delivery that resulted in a 42% reduction in carbon emissions.

In partnership with Network Rail, the team established a “green site” by using sustainable fuels, materials, and welfare facilities. The work involved the renewal of 1,418 metres of track on the down and up tunnel lines, along with adjustments to overhead lines.

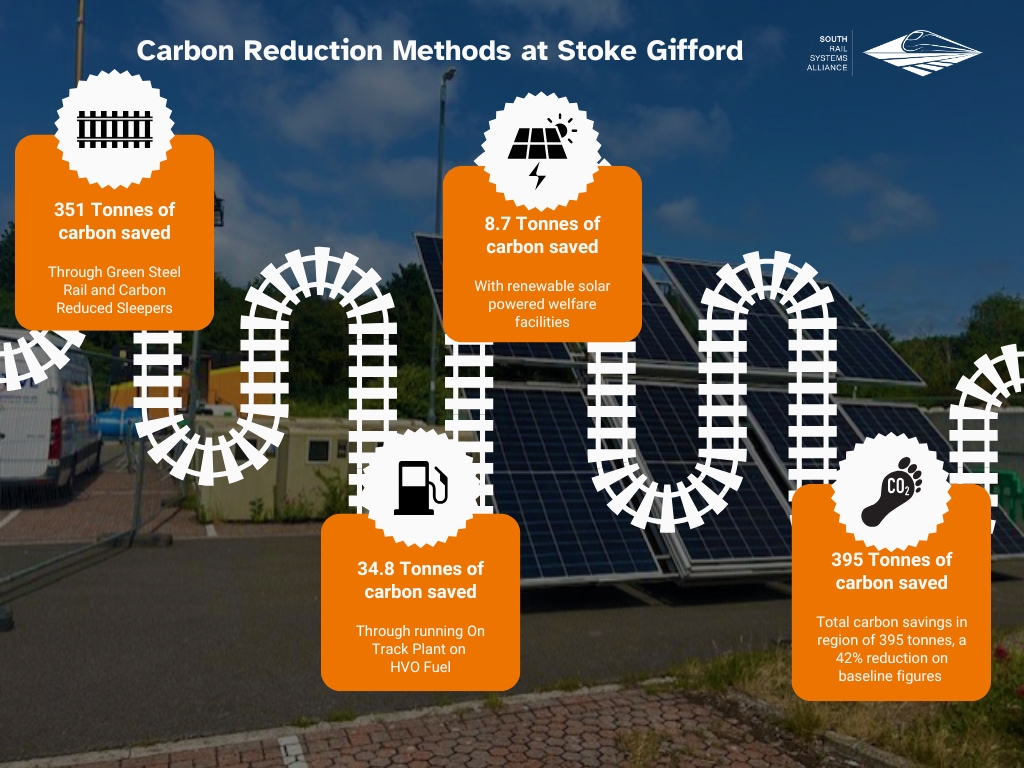

The significant carbon savings, totalling 395 tonnes, were achieved through a number of key measures:

- Green Rail: The team used rail produced via the Electric Arc Furnace (EAF) method, which utilises scrap steel. This change alone cut carbon emissions by 241 tonnes.

- Low-Carbon Concrete: Sleepers were manufactured with low-carbon concrete, contributing a further 110-tonne reduction.

- Sustainable Fuels: Road Rail Vehicles and the Tamper fleet were powered by Hydrotreated Vegetable Oil (HVO) instead of diesel, leading to a 34.8-tonne decrease in carbon output and reduced pollution.

- Battery-Powered Tools: The use of battery-powered tools on-site further supported the low-emission strategy.

- Solar Welfare Units: Solar-powered welfare units from SolGen were used, saving an additional 8.8 tonnes of carbon.

Shaun Hodges, Project Director at Colas Rail UK, said: “Delivering this scheme successfully, on time and without incident while using sustainable materials and tools is a proof of concept that we can take a big step in our journey towards a net zero railway. Engaging our trusted on track plant supply chain, tools and material suppliers to join us on this trial and embrace these greener methods were crucial in helping us reduce our carbon emissions substantially.”

Mark Parker, Lead Portfolio Manager for Network Rail and SRSA, said: “We’re delighted this work has been successfully completed with a real focus on sustainable delivery. Making small changes like these makes a big difference in reducing our carbon footprint. Cementing rail’s position as the greenest form of public transport is critical to the industry in the coming years and we are fully committed to working alongside our partners and contractors to achieve this.”